On Definable Features of Work

Using DFOWs Beyond Construction

Problems with the Modern DFOW Definition

The specifications serve as the primary basis for the DFOW list.

The DFOW list is created after construction mobilization.

Starter Questions

Do you understand what a Definable Feature of Work (DFOW) is?

Do you know how to create a list of DFOWs for your project?

How does your organization define a DFOW?

Why does a DFOW only apply to a project’s construction phase?

Can the DFOW be part of the standard, simplified language for quality?

Introduction

A mid-sized general contractor building an industrial warehouse near Memphis, TN created their Definable Features of Work (DFOW) log shortly before mobilization. The DFOW list originated from the project specifications. Each specification section became a DFOW and served as the basis for the Inspection and Test Plan (ITP). The construction team held the required planning meetings and intended to meet and exceed their client’s expectations by building per the plans and specifications. Twelve months later at substantial completion, the building was indeed built per the construction documents, but their client was frustrated and unhappy. The general contractor failed to understand the importance of the loading dock to the client’s operations. The design team also failed coordinate the electrical drawings and specifications for the dock equipment. Two mockups were missed, creating rework in two critical areas. Partnerships between all stakeholders diminished and the construction team did not win the next project with that client.

A Mixed Understanding of the DFOW

Construction organizations often utilize a Definable Feature of Work (DFW or DFOW) log in their quality programs to plan and inspect high-risk work. However, from one company to another, the definition of a DFOW is not consistent.

During Hanson Wade’s 2022 Advancing Construction Quality conference in Phoenix, AZ, I asked presenters and participants if their company had a standard definition for a Definable Feature of Work. I got the following responses:

A DFOW is the final element of a Work Breakdown Structure (WBS).

A DFOW is determined by the level of risk.

DFOWs are integrated assemblies.

DFOWs have special requirements above other project elements.

DFOWs are not only individual specification sections – it starts with them as a category of management.

DFOWs are not an individual trade’s work.

In my research [see Note 1], the term Definable Feature of Work (DFOW) originated from the US Army Corps of Engineers, which defines a DFOW as:

“a task which is separate and distinct from other tasks” (USACE, Construction Quality Management for Contractors: Student Study Guide, 2020, Pg 29)

The manual goes on to note the following DFOW examples:

Separate quality control requirements,

Trades, work crews, or disciplines unique to the task,

Critical path activity,

Monitored by a QC specialist or special inspection personnel,

As a minimum, each section of the specifications can be considered as a DFOW. However, there are several conditions that should be considered: 1) more than one definable feature under a section of the specifications; e.g. concrete formwork; rebar placement; and concrete placement, finishing and curing could each be a DFOW yet all or some may fall under a “Cast-in-Place Concrete” specification. 2) Another example is where a DFOW may require discussion across multiple specification sections for example concrete as a DFOW will have embedded items such as conduit and miscellaneous steel fabrications. [Emphasis is my own.]

I found other definitions as well. A research paper from Purdue University defines a DFOW as “[…] a single work activity as it relates to the specifications. For example, specification 03300 Cast in Place Concrete is a DFOW and will be tracked as an independent piece of work.” At the Sanford Underground Research Facility, the South Dakota Science and Technology Authority (SDSTA) states: “A DFOW is identified by different trades or disciplines and is an item or activity on the construction schedule. So, for example, excavation, electrical, concrete, roofing, mechanical, HVAC, etc. are all Definable Features of Work.”

I note these definitions to illustrate the complex terminology surrounding quality in the industry. A “task that is separate and distinct from other tasks” or a “work activity as it relates to the specifications” is not objective or tactical, making it difficult to manage for those installing the work - those with the greatest control over a quality result.

As teams strive to build per plans and specifications or exceed expectations, we don’t recognize that “[q]uality approaches that focus on satisfying requirements fail in recognizing […] that plans and specs might not be totally accurate, complete, or might not clearly express client expectations.”

This is the problem with leveraging only the project specifications as the basis for identifying Definable Features of Work. While the construction documents are a great communication tool, we underestimate two elements of managing a project:

How difficult it is for the designer to accurately capture and translate the client’s exact expectations into the specifications.

How difficult it is for the construction team to interpret and translate the client’s exact expectations from the specifications.

This is not the fault of the designer or contractor. The specifications alone are not sufficient to convey client intent – or mitigate other risks on the project.

The DFOW as a Framework

The industry needs a tactical framework for identifying Definable Features of Work that scales with project size, complexity, and team experience and incorporates the needs of our clients.

Let’s revisit the two problems with our modern understanding of a DFOW:

The specifications serve as the primary basis for the DFOW list.

The DFOW list is created after construction mobilization.

The first problem can be resolved by expanding our foundation of the DFOW to include:

Client Intent

High Risk / Critical Path Activities

Experience and Lessons Learned

Drawings and Specifications

The second problem can be resolved by promoting the use of DFOW in project phases outside of construction so all stakeholders are using the same building blocks to manage and understand the project. If the creation of the DFOW list began at the start of the project life cycle – and not at the construction mobilization, as is typical – the focus on what’s important to the client and planning can adapt and scale with the project.

This idea of the DFOW as a flexible, scalable framework also solves the problem of integrating Lessons Learned into the project (providing the right information at the right time) as well as adopting to the project’s specific conditions (geography, labor availability, client, product type).

The Enhanced DFOW Framework in Practice

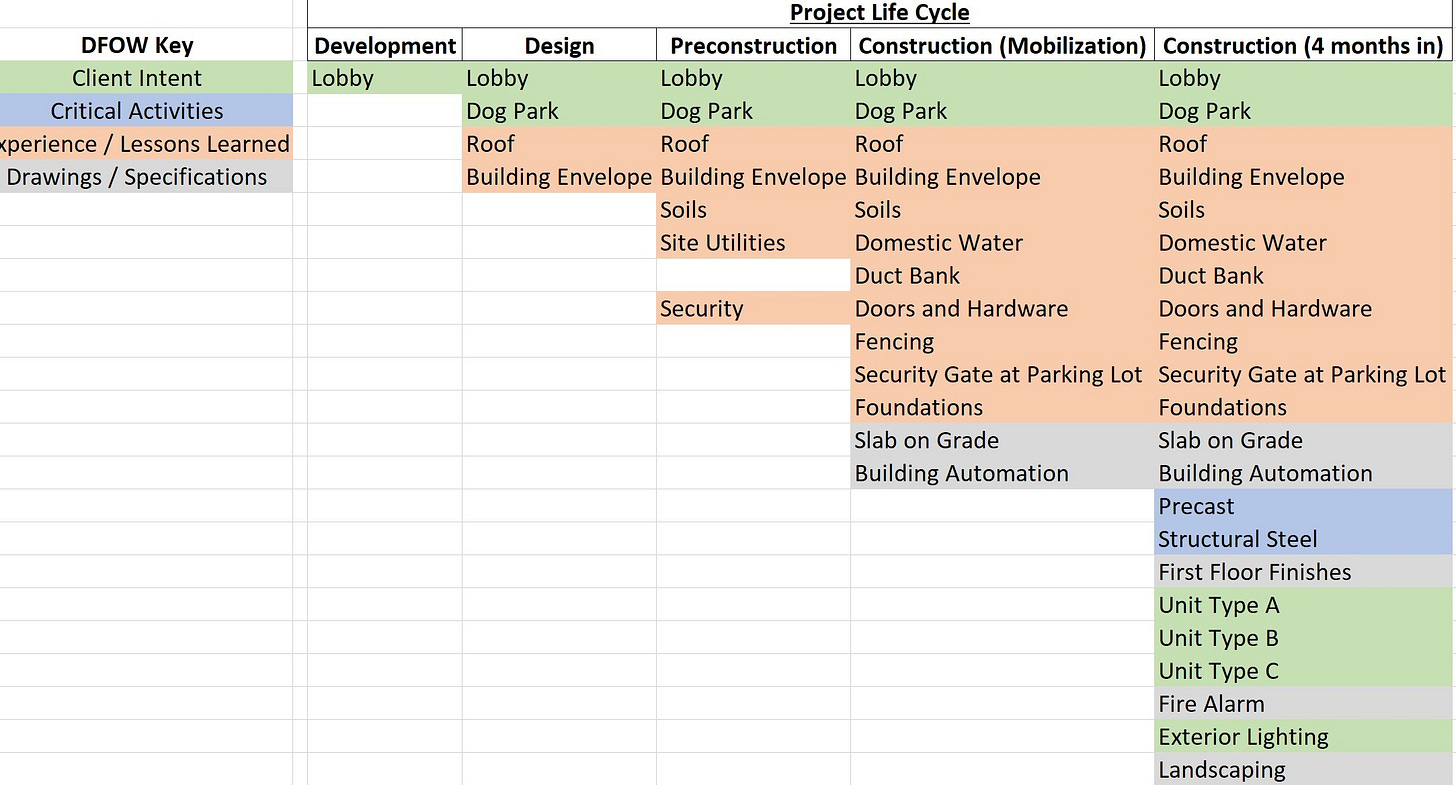

This enhanced DFOW Framework is applied to a hypothetical multifamily project below.

In Development, the client may state: “I envision a luxury condo where the residents feel at home when they walk in the building.” This comment could translate into the Lobby being a Definable Feature of Work.

Once Design starts, in addition to giving the Lobby special attention, the design team may note the importance of attachment details at the roof and building envelope, meaning they add Roof and Building Envelope to the list of DFOWs. The client may later inform the designer they want to have a dog park. The designer would add that to the list of DFOWs.

As Preconstruction begins, the estimators or design phase managers may recall the budget overrun on the last project in the region due to soils. Not wanting to repeat the same mistake, they note soils as a DFOW, in addition to site utilities. The Preconstruction department is also aware of the complexities of security and access in a multifamily project thus they add security as a DFOW.

Once a contractor is involved, they are given the list of DFOWs as a means of communicating the specific areas requiring special attention on the project. Also, now that the design is complete, the contractor reviews the Drawings and Specifications, further expanding the list of DFOWs by adding slab on grade and building automation. The contractor also notices the importance of security and makes that DFOW more specific by expanding it to doors and hardware, fencing, and the security gate at the entrance to the parking area. The contractor also provides additional focus to site utilities by updating it to domestic water while accommodating long-lead items such as precast and structural steel.

Four months into the project, the project team (inclusive of all stakeholders – not just construction) realizes there are other Definable Features of Work that are important to include. (Note that the list shown is not all-inclusive and simplified to articulate the general framework). The team discusses how they may plan for lighting, low voltage, finishes, and all other elements specific to the 300 units. They decide to identify each unit type (A and B) as a Definable Feature of Work where they capture the planning for everything within the unit type, which is repeated multiple times. (This would be more effective than trying to manage lighting or finishes for all 300 units as one DFOW.) In addition, the client told the team how important the exterior lighting is, given they want the building to showcase luxury during the evening hours. The team then added exterior lighting as a DFOW, noting it specifically as an element of the project that was important to the client. [See Note 2.] The contractor also added fire alarm and landscaping after further review of the specifications.

Notice the DFOW list grows throughout the project life cycle. The list is handed off from one team to another, revisited and revised as the project progresses. It becomes the primary handoff document - one that is tactical and concise. Also, in this enhanced framework, the DFOW list is continually reviewed with all stakeholders to confirm that areas of the project that are important to them – their intent – is appropriately captured. This is important because “intent can change over time or be subject to interpretation”. This is why a flexible framework is required: to manage the inevitable change in intent throughout the project.

For this to work, the designer must think about the DFOW just as the construction team does - not just in terms of design intent, a term that is often nebulous to the modern construction team. This shared understanding of the project would improve coordination and collaboration issues when transitioning to the next project phase.

The Future of Definable Features of Work

The core idea is to organize the project efficiently. The list of Definable Features of Work as a framework may be unconventional, but without a framework, project teams are pressured to give the same level of focus to everything, preventing them from being effective and clear on what is critical to stakeholders.

The means for organizing a project should be consistent across the project life cycle.

Creation of the DFOW list starts in the first conversation with a client.

DFOWs can also be a tool for the designer to communicate design intent to other members of the broader team.

The DFOW list can also be used to facilitate drawing and constructability reviews during design. At the start of each design phase or review, the DFOW list could be reviewed and reviewers assigned to each DFOW, making the review process more effective with the renewed focus on the high-risk elements of the project.

The DFOW list should be dynamic. This solves the problem of scalability in modern quality processes.

Returning to our story in Memphis, if this framework had been in place from the beginning of the project (not the beginning of construction, as is typical), the design and construction teams would have had the clarity to know what project elements required special attention – the loading dock.

We should all speak the same language when to quality. Simplifying our quality systems means simplifying our terminology, making the terms resonate with those who actually install the work and act as collaboration “swim lanes” through the entire project life cycle.

The Definable Feature of Work has power potential to transfer intent into the project – which is the definition of quality - and transform the industry.

Notes:

Please contact me if you can either confirm or correct my knowledge on the origin of the term DFOW.

In the early phases of the project, the client may not recognize the importance of this system.

Special Thanks

I am indebted to Mike Jones, Jennifer Groen, and the late Scott West for feedback and input on previous versions this article. Their knowledge and expertise are invaluable.

Also, the definition or framework presented here is not the industry standard. It is my own based on my experience and what I feel is essential to the overall project life cycle. I do not intend to criticize any existing definitions or opinions of the term Definable Feature of Work. This framework was a result of my own study to better understand the terminology myself.